Salt Spreaders for Electric Vehicles

The Polaro spreader range draws only 30% of the current needed by other electric salt spreaders. This makes it perfect for electric vehicles.

Polaro spreader explanation

Not only does the electrical system on the Lehner Polaro Range make it one of the most reliable spreaders on the market. It also makes the machine uniquely suitable for electric vehicles. Utility vehicles like the Garia pictured below require most of their power to propel the vehicle.

If this becomes unnecessarily burdened by attachments with a high current dray (such as most electric spreaders on the market) it will deplete the battery very quickly.

The Polaro range only draws about 30% of the current needed by other spreaders on the market.

This means it is much less of a strain on the vehicle, which will cope with the draw much better and allow the batteries to last much longer before the next charge.

The Motors

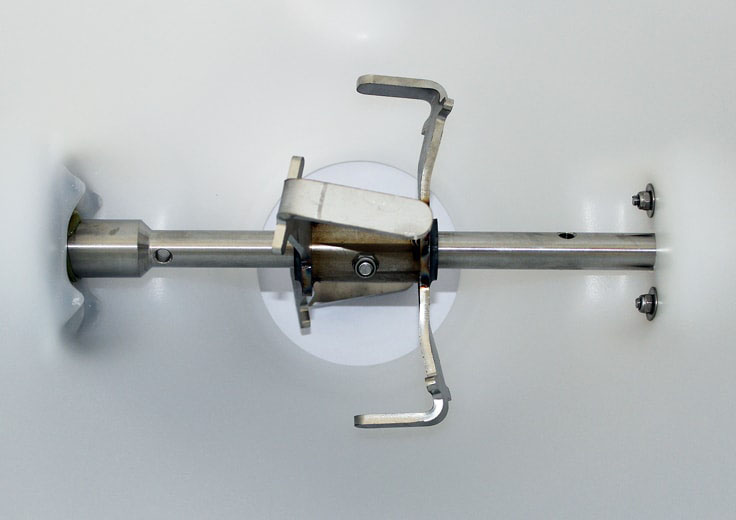

The motors that operate the agitator and spinner are the heart and lungs of the spreader. Making sure they operate reliably is probably the most important thing in any spreader.

The Polaro has 2 completely sealed IP67 rated motors. Each one specifically designed for its unique job.

- We have one high speed motor for the Spinner, controlling the spread width. Which operates from 0-6m.

- A second motor for the Agitator to get the salt through the system freely, operating at a much lower speed and higher force.

Dosage is controlled using a manual setting to further reduce the current draw.

Using the two patented purpose built motors we have greatly increased the reliability of these spreaders versus others on the market.

In machines that rely on a single motor operating both spinner and agitator - both components must operate at the same high speed required for the spinner. This puts excessive strain on the motor because too much force is required to turn the agitator at high speed through damp claggy salt. To overcome this, manufacturers need to use much smaller agitators, which then require a vibrator to bring the salt into the agitated area. We are able to use a much larger agitator and do not require the vibrator. This leads to much less compaction of the salt in the hopper.

As a result, we put far less strain on the electrical components, with the motors all operating well within the designed operating parameters, reducing high loads on the motors and fuses. This has almost eliminated motor failures on our spreaders.

The Controller

If the motors are the heart and lungs, then the controller is the brain.

The controller allows us to operate the individual motors for precise spreading width.

The spinner can be set between 0 and 600rpm to achieve a spread width up to a maximum of 6 meters. The spinner speed controls the width of spread, so you are not relying on baffles. If needed a different motor option is available increasing the maximum spread width to 12m.

A digital readout makes selecting the spinner speed extremely easy.

The controller has a warning light to indicate blockages or an empty hopper - making it easy to tell if there is a problem.

The controller is hard wired to the spreader with watertight connections providing the most reliable connection possible.

Other components

All mechanical parts on the spreader including the spinner and agitator are made from stainless steel for optimum corrosion resistance.

The screw on lid keeps the material in the hopper drier and creates a much more positive seal than the clip over lids found on other machines.

The spreaders are very easy to maintain with handy features such as accessible grease nipples. The hopper can be removed from the base with 6 handwheel bolts, so everything is easily accessed for cleaning or other maintenance tasks.

The handles on the side of the base allow you to move the spreader around when the load has been emptied.

For more information on the Polaro E, check out our web page;

https://kerstenuk.com/Lehner-Polaro-E-Tailgate-Mounted-Spreaders

No comments yet. Login to start a new discussion Start a new discussion